Benefits of Using Hot Dipped Galvanised Steel

When it comes to building structures that withstand the test of time, the choice of materials plays a crucial role. One material that has gained...

With a solution-focused approach, we collaborate closely with clients and consultant teams to align on scope, time frames, design objectives, and cost. We’re committed to delivering a strong return on your investment. Are you interested in our work in the commercial and industrial sectors?

Our client, a vet and sheep farmer, needed a shearing shed and yard cover designed for efficiency and innovation. Partnering with our team, he collaborated with fit-out providers to create two custom steel structures tailored to his farm’s needs. His farm is now equipped for better working conditions and long-term success.

Providing Industry-Leading Steel Building Solutions

Central Steel Build, committed to innovation, quality, and customer satisfaction, has solidified its reputation as an industry leader. We're revolutionising agricultural structures, and transforming how farmers and producers approach building solutions. If you’re interested in our work in the agricultural sector, read the article to discover how we’re transforming building solutions.

Oritech combined office and warehouse

Oritech Pty Ltd partnered with us to build a modern office and warehouse facility in Mitchell Park, Victoria. The design featured innovative L-shaped tilt panels for both function and style. Using our Pro. building approach, we delivered a durable, cost-effective, high-quality solution. Seamless collaboration ensured the project was completed on time and within budget.

1 min read

![]() Central author

Jun 5, 2019 2:24:50 PM

Central author

Jun 5, 2019 2:24:50 PM

All steel products are susceptible to rusting when they come into contact with oxygen.

Rust can be stopped by hot dip galvanising as a lasting solution or by painting over the steel which provides a short term prevention.

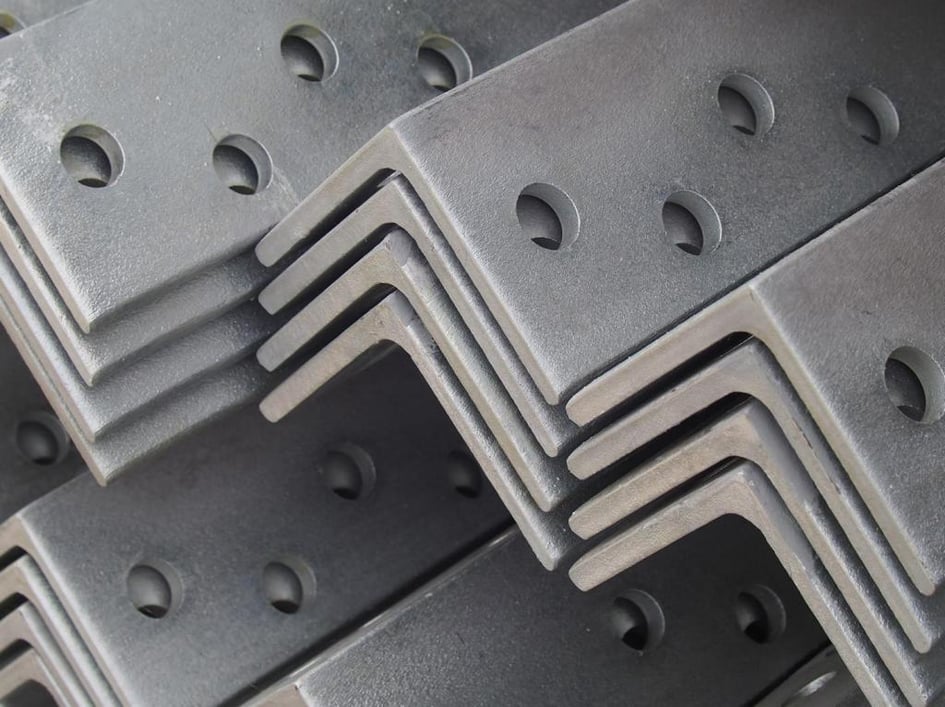

This is the process of immersing steel into molten zinc to coat it. Zinc bonds with the steel to form an anti-rusting and anti-corrosive coating. Hot dipped galvanised steel is used for many different functions including roofing, automotive parts and heating and cooling conduction systems. The coating has a lifetime of over 50 years in most weather conditions and requires hardly any maintenance.

Hot dip galvanising is the process we use on all of our sheds, it is proven to be the best and longest-lasting way to protect your steel.

This method can be more aesthetically appealing to some who prefer a colour to the silver triangular pattern that zinc coating creates. Coating paints can serve well to protect steel from high temperatures, insulating the steel from fire. However, paint coating has a 12-15 year lifetime and steel that is painted often becomes exposed to rust if the paint is scratched, chipped or dented before then.

When it comes to building structures that withstand the test of time, the choice of materials plays a crucial role. One material that has gained...

Not all steel is created equal — and for long-lasting builds, the difference between adequate and exceptional comes down to the choices made before...