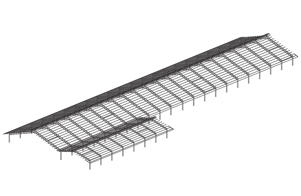

Custom-made feedlots, every single detail counts

Good design minimises operating costs and results in a functional, efficient, and profitable feedlot facility. Your business will only benefit from our specialised industry experience in feedlot facilities.

The space

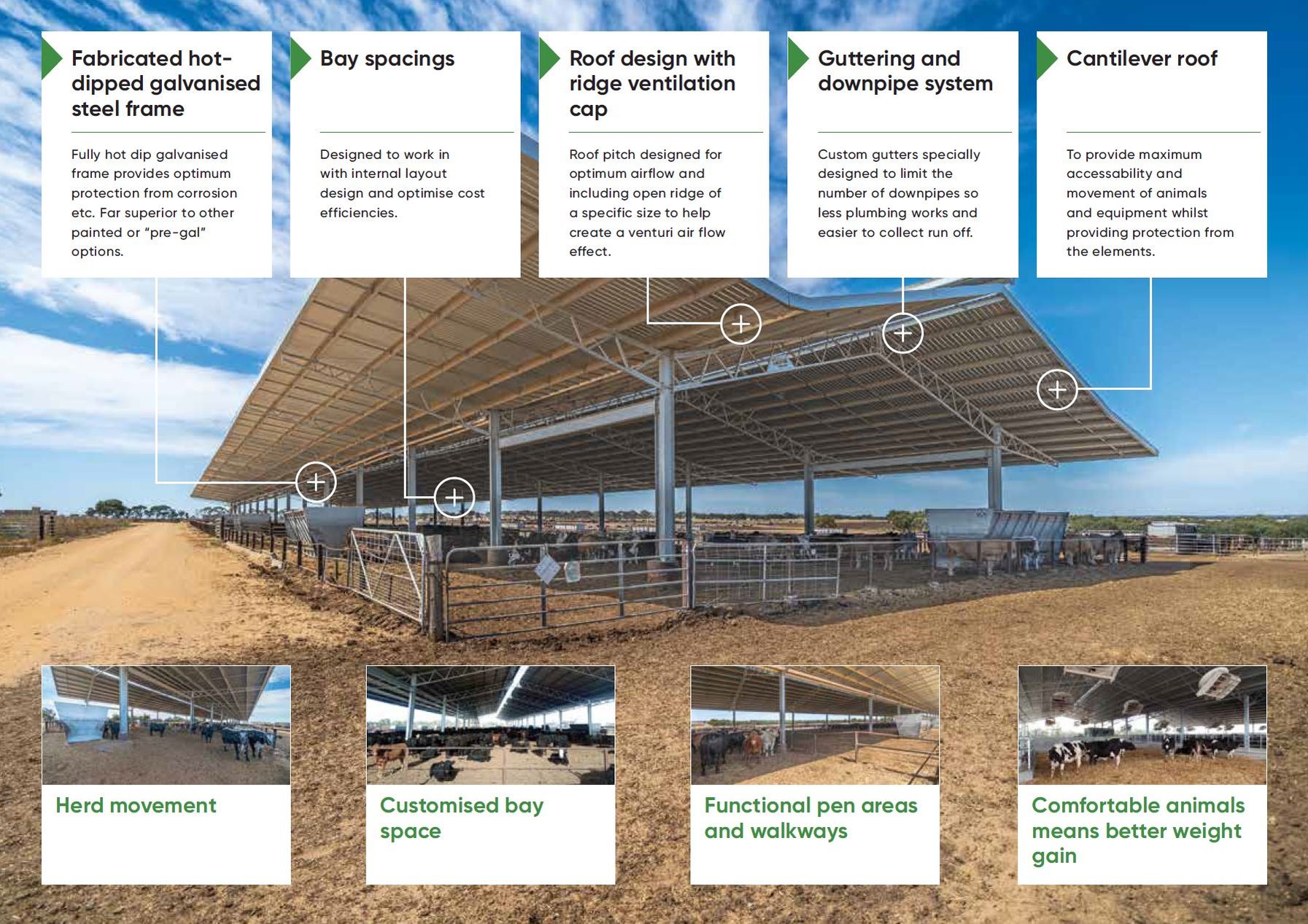

Whether it’s for your cattle, sheep or pigs, we work closely with both you and your fit out provider to purpose build a feedlot solution. Our industry specialists design to address all the common feedlot challenges including airflow, ventilation, feed lanes and feed wagons, heat stress, storm water run-off, flush lanes and herd accessibility.

Our hot dipped galvanised steel frames add an extra layer of protection in these typically corrosive farming environments. To ensure top-class animal welfare practice, we customise bay spaces, pen areas and walkways. The result is a highly-functional, efficient, and profitable feedlot. Building to existing terrain levels and over existing yards is a Central Agricultural specialty.

We do things differently

Our flexibility, experience and know-how are unrivalled in this industry, which is why nearly three quarters of our total business comes from referrals or reorders. There’s a reason why so many businesses trust us to get the job done right, and why you should trust us too.

Our hot-dipped galvanised Australian steel is a game changer in this industry - built to last for more than 50 years in most rural environments. This means you can get on with the business that matters without having to worry about your sheds or your assets.

“Central Steel Build was able to provide the feedlot cover we had designed at a competitive price on the day. The build was seamless with the company representatives easy to work with and keen to provide assistance when it was needed.”

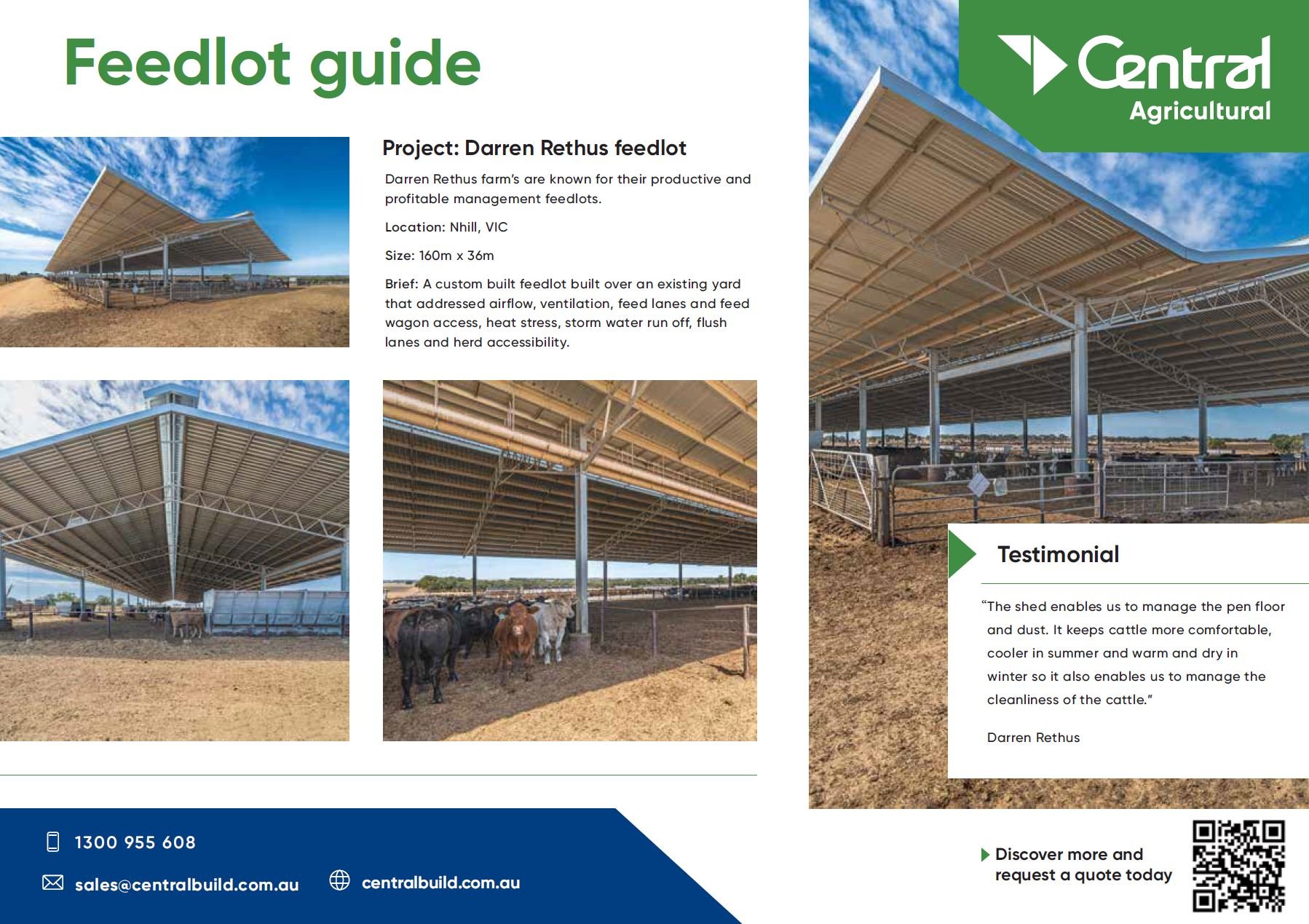

“The shed enables us to manage the pen floor and dust. It keeps cattle more comfortable, cooler in summer and warm and dry in winter so it also enables us to manage the cleanliness of the cattle.”

“The process was easy, which is a great compliment to give a company.”

Featured agricultural shed project case study

Darren contacted us to build a feedlot that would improve working conditions for himself and his workers and the living conditions for his beef cattle. It was imperative that the design of the building would increase on-farm animal welfare for Darren’s cattle. The feedlot was to be built over existing yards on uneven ground so our challenge was to ensure the shed would not inhibit the working ability of the yards and was built to suit the lay of the land.

3 min read

Why Steel Choice Matters: Getting it Right from Day One

2 min read

Top Advantages of Using Clear Span Sheds

Love what you see?

Get an obligation free quote today.