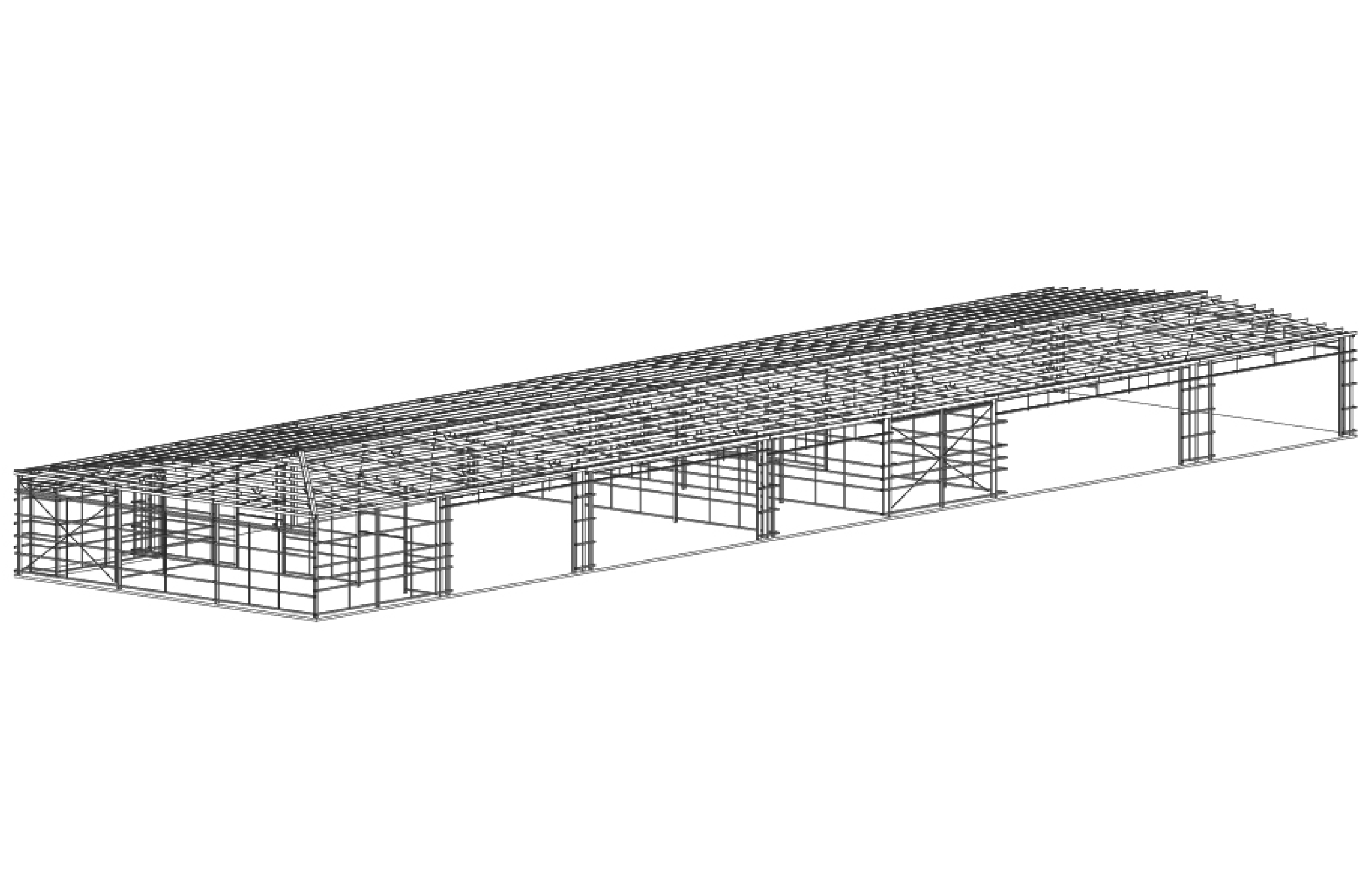

Powercor industrial workshop

Project overview

CSB was originally asked to quote for the tender on the pre-engineered structure fully scoped out by architects, engineers, and the builder. We did this, then offered them a lot of advice and cost savings to change things like cladding profiles, roofing profiles, gutter design, and profiles, and re-engineer the main structural steel for a more economical design. They accepted nearly all our recommendations, which saved hundreds of thousands of dollars over the course of the job.

- $700K-1M*

- 14 weeks

- Kyneton, Victoria

- Raysett Constructions under B2B Construction

- Architect

- Structural engineer

- Geotech consultant

- Project management co.

- Structural steel drawings, engineering certification and computations.

- Structural concrete engineering including slab and footing design.

- 3D structural/shop steel drawings.

- Fabricated hot dipped galvanised steel package.

- Purlins and girts.

- External steel cladding.

- Industrial fire egress compliant access doors.

- Guttering and above ground rainwater systems.

- Extra large door openings with girder beams.

- Soffit lining.

- Architectural angled cladding.

- Hip roof.

- Internal walls and inset walls.

*All prices are an indication only and are subject to change at any time due to industry steel prices. The prices also do not include erection or site preparation.

Challenges and solutions

With very large span openings for the client's own large doors, the use of girder beams along with the removal of columns was a well-considered solution. The end design used a hybrid design of eave girder beams plus a ridge girder beam to help spread the load of the large openings.

Going through multiple layers of builders minus direct access to the decision-makers, the process became fairly long for sign-off, but in the end, the economical approach was well received and the client went with a lot of the cost-saving options.

We were instrumental in saving the client a significant amount of money. The design team (along with the engineer) did a great job of coming up with economical design solutions and engineering.

Love what you see?

Get an obligation free quote today.